DEC stud welding is a classic welding process that can weld many materials, is applicable in many industries and is quite simple to set up. A current discharge from the capacitor is applied to the stud to initiate the arc and force the stud to be welded to the workpiece. This process is often used to avoid penetration, damage or deformation when machining thin sheet metal.

C2G offers you the possibility to buy online your welding studs in steel, brass and stainless steel. If you wish, you can also request a quote directly from our online shop.

DEC stud welding: choosing speed and strength for maximum possibilities

Whether in steel, stainless steel or brass, DEC stud welding from C2G offer many advantages:

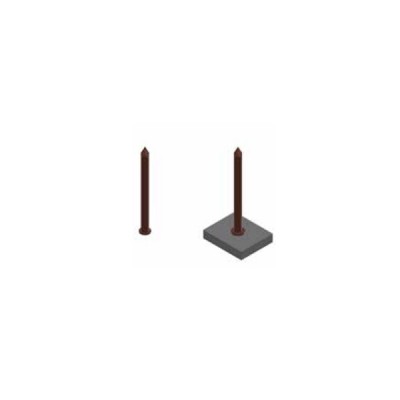

1. Performance: with the DEC welding process, the welding of studs from 1 to 10 millimetres is of high quality with no burrs or deformation.

2. Installation: DEC stud welding is very simple to install, a tip on the end of the stud which is placed in contact with the substrate.

3. Materials: DEC stud welding can weld many materials and has very good results on steel, stainless steel or copper alloys like brass.

2. Installation: DEC stud welding is very simple to install, a tip on the end of the stud which is placed in contact with the substrate.

3. Materials: DEC stud welding can weld many materials and has very good results on steel, stainless steel or copper alloys like brass.